Self-passivating tungsten alloys

To optimise the safety properties of a future power plant IPP is developing tungsten alloys which safeguard themselves against oxidation when they come into contact with oxygen.

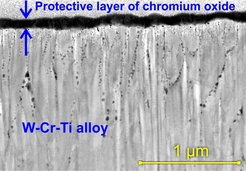

Electron-microscopic cross-sectional image of a tungsten alloy after oxidation at 900 °C: The protective chromium oxide layer appears in the upper part of the image as a dark belt.

Figure: IPP