Innovation Award of the German Copper Institute for IPP Scientist

Alexander von Müller receives award for the development of tungsten-copper composites

IPP scientist Alexander von Müller was awarded the Innovation Prize of the German Copper Institute. His work on “Melt-infiltrated tungsten-copper composites as heat sink materials in plasma-loaded components” according to the prize committee represents “a groundbreaking contribution to the development of innovative products made of copper and copper alloys”.

The composite materials developed by Alexander von Müller and his cooperating partners will be used as water-cooled heat sink materials to protect particularly stressed parts of the plasma vessel in a future fusion power plant – the places where the hot plasma, magnetically suspended in front of the walls, comes into contact with its vessel.

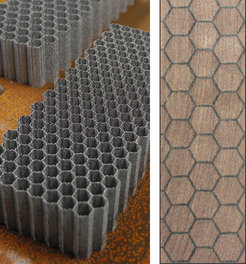

Tungsten, the metal with the highest melting point, is well suited for this purpose, above all because of its resistance to the impact of fast plasma particles. However, the metal is also very brittle, which is why it is supplemented by the ductile, heat-conductive copper. The production of the tungsten-copper composite is ingenious: A porous tungsten body serves as a preform. It is produced either from thin tungsten fibers, by sintering tungsten grains together or – particularly demanding – in 3D printing from tungsten powder melted in layers by laser. The resulting open-pored structure is “infiltrated” with copper, which is heated above the melting point: The liquid copper creeps into the porous tungsten structure and fills the gaps.

The annual Innovation Award of the German Copper Institute is a funding competition for students, doctoral students and scientific staff from all areas of engineering and natural science in research and industry. The submitted papers are evaluated by independent jurors from the copper processing industry and research. Alexander von Müller will receive the 2,500 Euro award on 21 November 2019 at the Copper Symposium in Dresden.