Tungsten-copper composite materials

Tungsten-copper composites are investigated as high-performance materials for heat sinks in plasma-facing components

The exhaust of power and particles is currently considered as one of the ultimate challenges for a future demonstration fusion reactor. Predominantly challenging is the design and manufacturing of the plasma-facing components (PFCs) of the divertor. During operation, they have to sustain intense particle, heat and neutron fluxes. Current state-of-the-art designs for water-cooled divertor target plates make use of tungsten as a plasma-facing material, while copper alloys are regarded as most appropriate materials for the heat sink.

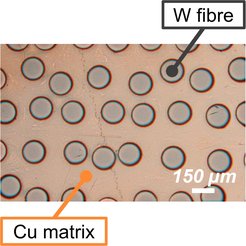

However, issues arise when such a design is applied to a demonstration reactor: Copper alloys as structural heat sink materials in PFCs are problematic due to the behaviour of these materials under neutron irradiation. They suffer from a pronounced loss of ductility at lower and a loss of strength at elevated operating temperatures. To address this issue, members of the Plasma Component Interaction group are developing tungsten-copper (W-Cu) composites as potentially advanced heat sink materials for highly loaded PFCs. Such metal matrix composites can exhibit outstanding material properties which allow PFC designs with improved heat flux performance. The figure illustrates the microsection of a tungsten fibre-reinforced copper composite material utilising high-strength tungsten fibres embedded in a high conductivity copper matrix.