Advanced tungsten-based materials

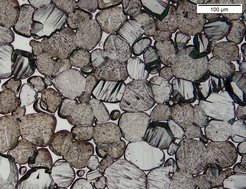

For instance, tungsten is a brittle material, so it can crack and is difficult to machine. To improve the applicability in this respect there are two kinds of developments going on at IPP: On one hand there is the research on reinforcement of tungsten with tungsten fibres, which is conducted in cooperation with Forschungszentrum Jülich. The fibres introduce more toughness into the material. On the other hand IPP is testing the applicability of so-called tungsten heavy alloy as a plasma-facing material. This a commercially available sintered material consisting of tungsten grains embedded in a nickel/iron alloy matrix. The matrix represents only five weight percent, so the material essentially consists of tungsten.

Another disadvantage of tungsten: its oxide can evaporate at temperatures above 1000 °C, which is an unwanted effect. To prevent this the Spanish research centre CEIT develops oxidation-resistant alloys, which are tested and investigated at IPP.