Launching systems

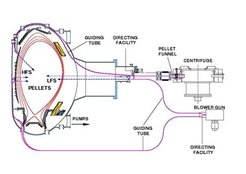

The first step was the injection directly from the outside of the tokamak, into the magnetic low side (LFS) using a centrifuge at pellet velocities from 240 m/s to 1000 m/s. After that, narrow bended tracks were applied in the vessel but were not found capable of high speed launch.

It was postulated that an improvement in refueling-efficiency could be achieved if the injection was realized from the magnetic high field side (HFS). A proof of principle was done: Pellets were injected from the LFS and the HFS with a blower gun at a pellet velocity of 240 m/s. The results confirmed the assessments. In order to reach higher repetition-rates the experiment was reapeated with the centrifuge and an guiding system. Due to the high forces applied to on the pellets during the flight through the tube, the guiding system had to be improved.

A new complex injection setup employing a looping geometry was built for the HFS of ASDEX Upgrade. A major constraint for the design was the location of the technically complex ASDEX Upgrade centrifuge, which was found to be virtually unmovable. The only feasible option was a rotation of the centrifuge by 180 degree such that pellets are accelerated away from the tokamak and then guided back to the torus HFS side by a roughly elliptical track.

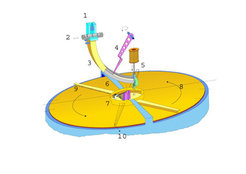

2. Centrifuge:

1: Extrusion Cryostat

2: Extrusion Nozzles

3: Storage Cryostat

4: Lever

5: Cutting piston

6: Fuel rod

7: Stop cylinder

8: Acceleration way

9: Outer Acceleration arm

10: Pellet exit