Organisation

The Wendelstein 7-X stellarator is at present being handled by eight groups.

Subdivisions of the Wendelstein 7-X project:

- Project coordination

- Design engineering

- Assembly

- Operations

- In-vessel components

- Magnet and cryo technology

- Data acquisition and controlling

- Plasma heating and core diagnostics

- Edge and divertor diagnostics

- Dynamic and transport diagnostics

Contributions are also being made by Greifswald's Technical Services along with the Integrated Technical Centre and the KIP Group at Garching.

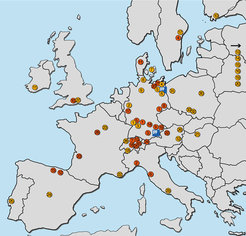

Firms throughout Europe were manufacturing individual components for Wendelstein 7-X, and numerous research institutes were involved in construction of the device: For example, Karlsruhe Institute of Technology were developing the microwave plasma heating and are responsible for providing the entire microwave system. Jülich Research Centre manufactured the connecting components for the superconducting magnet coils and took on diagnostic development work.

Over 160 person-years of work was invested by specialists in superconductivity technology from the Polish Academy of Sciences at Cracow to install the connections of the stellarator coils. The fusion institutes at Princeton, Oak Ridge and Los Alamos contributed auxiliary magnetic coils, measuring instruments and planning of sections of the wall cladding to a value of 7.5 million dollars for equipping Wendelstein 7-X.